Ingenious innovations

Chewable Fabrics

01

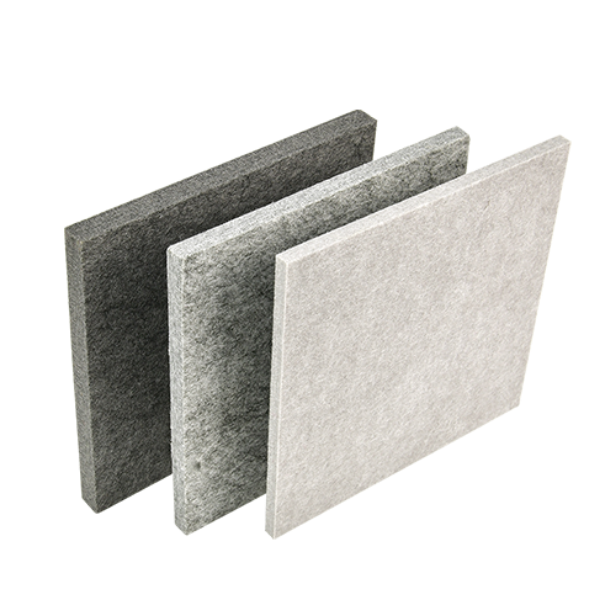

We have developed a unique material that allows additives to be assimilated into its configuration and released when exposed to the dynamics of in-mouth use by chewing. Additives include flavours, nicotine, caffeine, and pain relief chemicals. The material is designed to release additives in a controlled manner via the ‘chewing process’ without a major deterioration to the structure of the fabric.

Constructed with or without binders, the material is made using food and medically approved fibres bound in a variety of ways that ensure a comfortable and agreeable mouth sensation. These methods include needling, stitching, fibre entanglement, or the incorporation of fusible fibres. The product can be cut and packed into any shape or size using standard packaging techniques commonly available to the packaging industry.

We have also created a resilient, chewable nonwoven fabric capable of withstanding chewing or sucking in the mouth without disintegrating. When this specially constructed nonwoven fabric is used to form a pouch, it stops the contents of the pouch – such as nicotine containing media, pharmaceuticals, coffee, tea or other flavoured contents – from escaping into the user’s mouth.

This resilient fabric can be made by laminating together a traditional nonwoven substrate of fabric with a strong, chewable, permeable layer of material made for example with thermoplastic polyurethane (TPU).

Chewing this specially constructed nonwoven fabric can in fact increase its liquid permeability, thereby controlling the release of substances from within the pouch and improving the transfer of flavours into the user’s mouth. The durability of the fabric in the mouth lasts at least 10 minutes or more which is the normal consumption time for a pouched product.

We seek to protect our intellectual property in this area. See for example our patent applications WO 2021/219494 and WO 2022/112085