Case Study

Improving Performance

01

Challenge

We were challenged by one of Europe’s largest facemask manufacturers to improve the production and performance of their finished masks. To optimise their production process, we needed to assess their lead times, logistics, stock availability and surge demand fulfilment.

To enhance the performance of their masks, we needed to review the low quality activated carbon layer that was failing the client’s product.

02

Solution

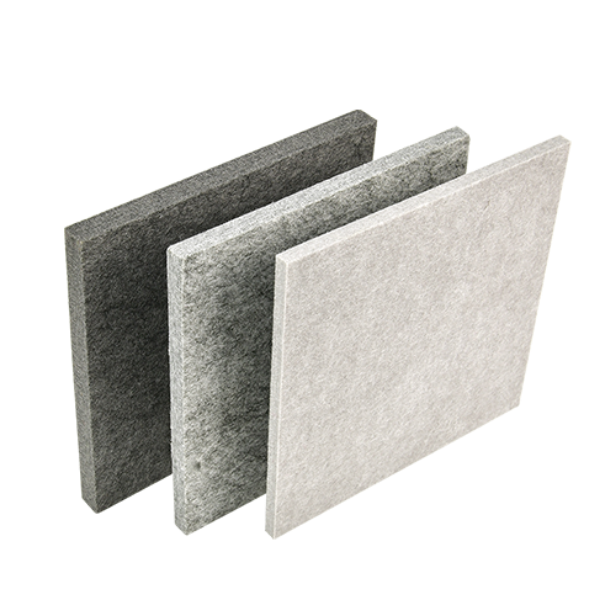

Our innovations team developed a polyester-based, thermally-bonded nonwoven fabric to replace the low-quality carbon layer. This revolutionary solution was lightweight, breathable, and met the client’s precise low-pressure drop requirements. It also carried sufficient carbon to meet the challenge of absorbing organic vapours.