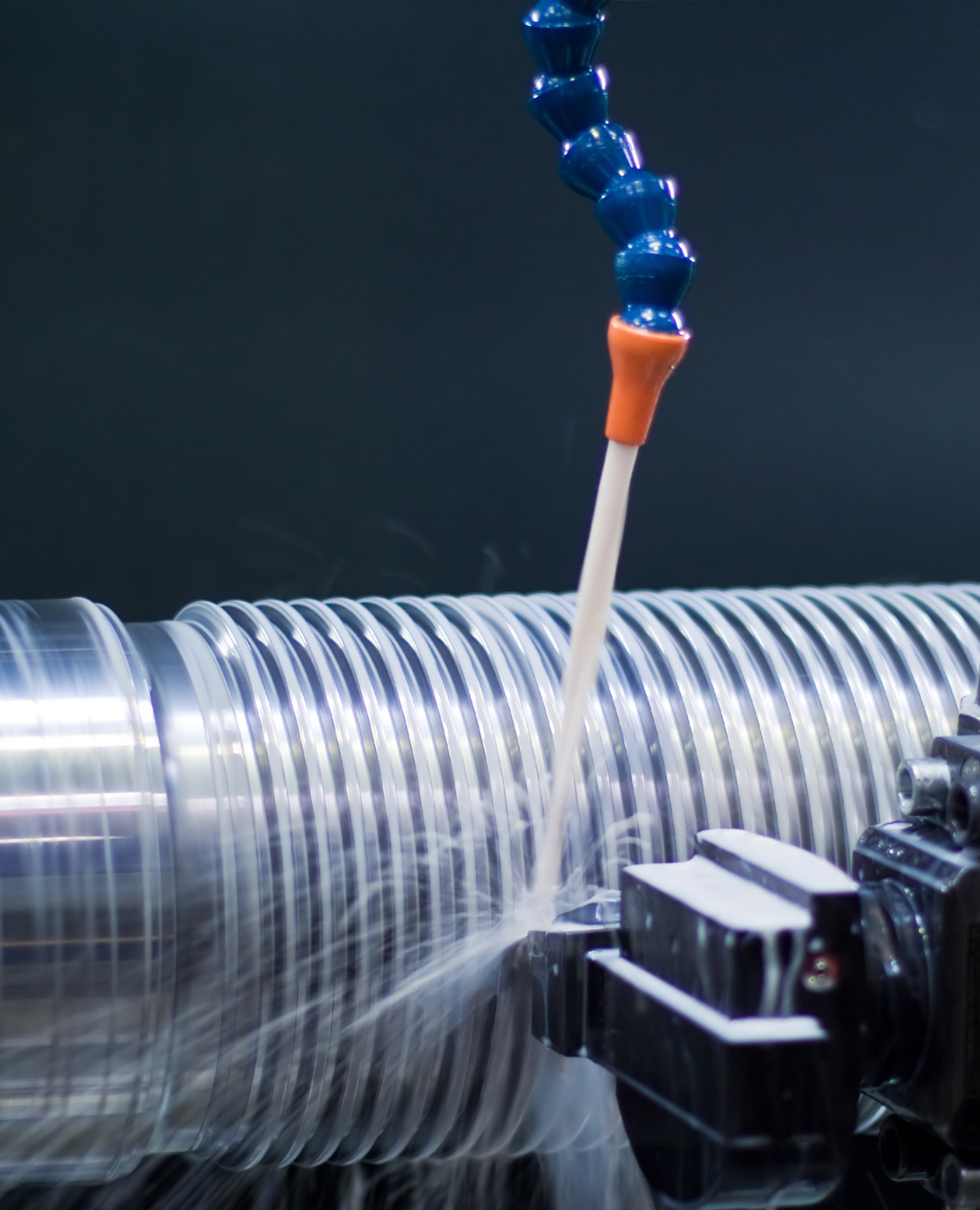

Industrial Filtration

We work closely with you to enhance your products, with peerless levels of protection and safety across a range of applications, including:

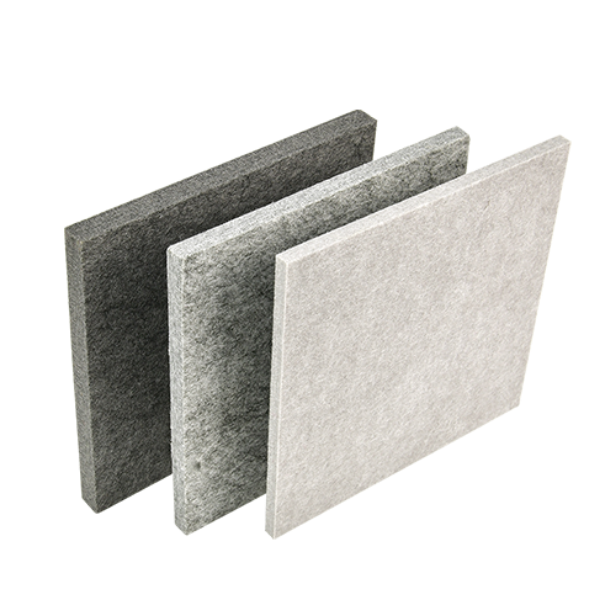

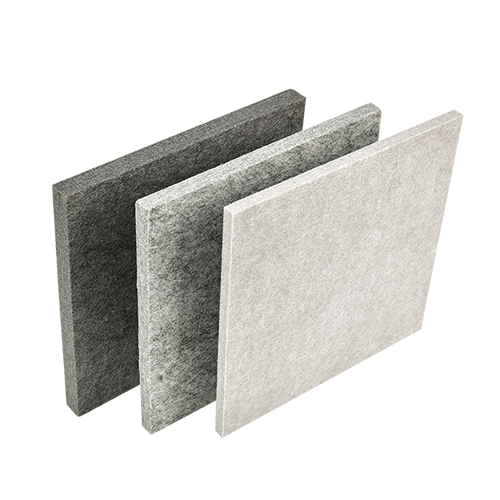

Acoustics

We work closely with designers, architects, and manufacturers to create bespoke nonwoven fleeces used in the manufacture of ceiling tiles, helping to absorb unwanted environmental noise.

Agrotextiles

Few can match the way our solutions boost protection and performance in agriculture. Our profound expertise enables us to optimise the functionality, so your crops can thrive and flourish.

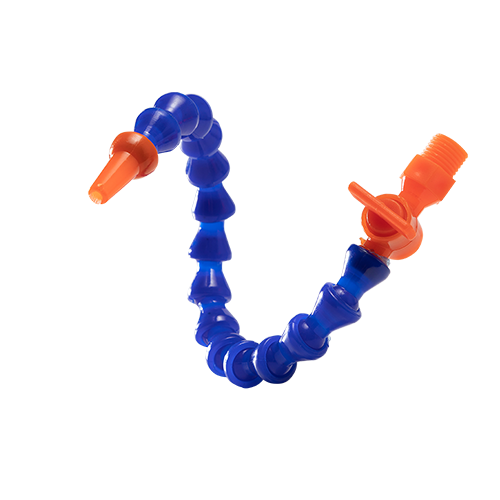

Cable & Telecoms

We understand the importance of using reliable fabrics to buffer and bed your industrial cables.

Embroidery Backing

Our advanced backings support fabric during stitching, with different designs and stabilisation requirements for specific types of embroidery.