Ingenious innovations

Chemical & Thermal Bonding

01

We have adapted our chemical engineering expertise to create thermally bonded modern oral pouch fabric without incorporating binders, using a ‘chembond’ process.

At Nonwovenn, our innovations experts and engineers have been able to modify our chemical bonding process to create soft, strong, thermally bonded fabrics that can withstand mastication whilst creating a softer feel in the mouth all without the need for chemical binders.

By utilising our existing ‘chembond’ technology, our team can create nonwoven fabric for oral pouch products by using thermal – or heat bonding techniques whilst eliminating the need for any chemical binders.

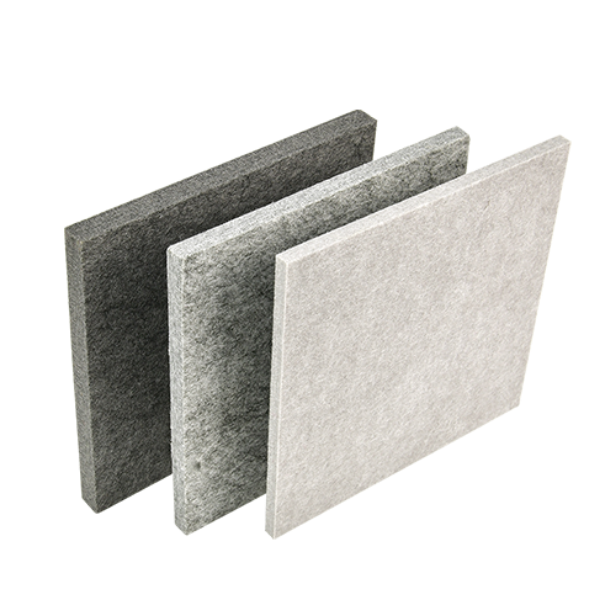

We use thermal bonding to carefully combine staple fibres, such as Lyocell, with thermoplastic fibres to offer mechanical integrity. The resulting nonwoven fabric is robust, highly resilient, and remains capable of withstanding manipulation in the mouth while retaining a soft, desirable mouthfeel experience for the user.

Additionally, the liquid permeability of the fabric, is not compromised. This allows the controlled release of active ingredients from within the pouch– be it nicotine, flavours, coffee, tea or pharmaceuticals.