Ingenious innovations

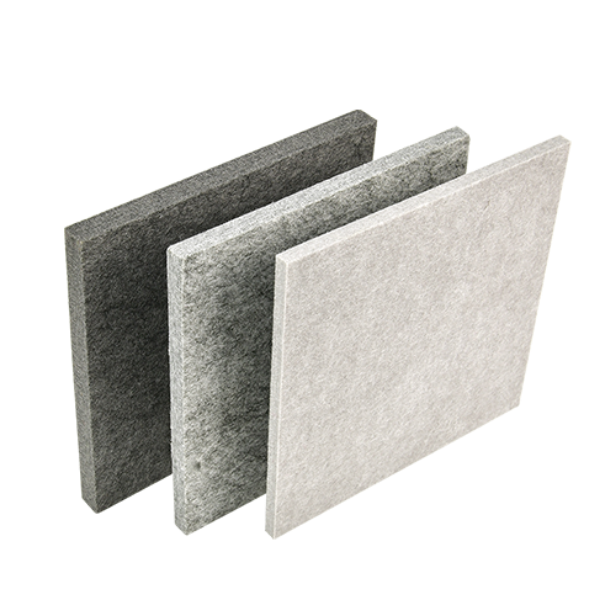

Lyocell-based fabric

01

Lyocell: a staple fibre suited to the future of modern oral products

Lyocell is a form of regenerated cellulose which can be obtained by direct dissolution of wood pulp.

Lyocell fibres typically have a higher degree of cellulose crystallinity compared with viscose fibres. This gives Lyocell fibres a fibrillar structure that can greatly influence fluid transport and flavour transfer across the constructed nonwoven fabric.

Nonwovenn’s research and development experts have discovered that this property can be used to provide a nonwoven fabric with improved stability for use with substances contained in modern oral products. For example, the nonwoven fabric can exhibit a reduced absorbency of the types of micro-sized materials that are used instead of tobacco-based substances in modern oral products. Lyocell-based fabric remains capable of withstanding manipulation in a user’s mouth when sucked or chewed, while retaining a desirable mouthfeel experience for the user.

Pouches made from Lyocell fabric are used to package and deliver smokeless tobacco flavouring and are particular suited to modern oral products containing tobacco-free nicotine, pharmaceuticals, coffee and tea etc.

Lyocell is also one example of a staple fibre that can be manufactured in a sustainable manner, through the use of non-toxic solvents and water used for dissolution which are then fully recycled. Our team is able to create fully compostable, biodegradable nonwoven fabric for oral pouch products by carefully combining biodegradable staple fibres, such as Lyocell, with biodegradable binders. The resulting nonwoven fabric is fully compostable and manufacturable in a sustainable manner, and yet does not compromise on wet strength.